Englist

Important components of the suspended scaffold platform

Working platform: steel with painting or galvanized, aluminum alloy

LTD Series Hoist: High-quality Die-casting aluminum casing

LSF Series Safety Lock: Anti-Tilt type for end stirrup platform

Electrical Control box: First class electrical components

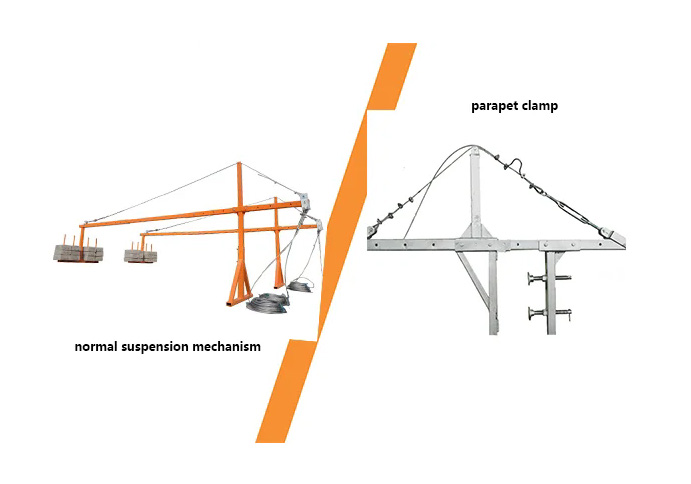

Anchoring Options: normal suspension mechanism or parapet clamp bracket

The use of high-quality aluminum alloy material, with high strength, low density and good corrosion resistance, making the platform overall light and durable. The platform is fixed on the building structure by the suspension mechanism, which realizes the freedom and flexibility of high-altitude operation. The main body of the platform adopts the hanging basket design, which provides a spacious, comfortable and safe working environment for the operators. The height, length and width of the platform can be adjusted to suit different building structures and operating environments.

Suspension mechanism or parapet clamp, chosen according to actual usage scenarios.

Length can be adjustable, aluminum alloy or steel(painting or galvanized optional)

The materials and parts used in the hoist are top quality. This makes the hoist strong and reliable. It also provides great life expectancy.

First class electrical components, professional waterproof design, and individually marked wires for easy identification.

Anti-Tilt type for end stirrup platform, a separate mechanical unit that can automatically lock safety wire rope when the working wire rope is broken or suspended platform tilts to its limits.

| Model | ZLP300 | ZLP500 | ZLP630 | ZLP800 | ZLP1000 | ||

| Rated Capacity | 300kg | 500kg | 630kg | 800kg | 1000kg | ||

| Rated speed | 7~9m/min | 9~11m/min | 9~11m/min | 8~10m/min | 8~10m/min | ||

| Platform Width | 3m | 5m | 6m | 7.5m | 7.5m | ||

| Powered Unit: Hoist | LTD3 | LTD5 | LTD6.3 | LTD8 | LTD10 | ||

| Steel Wire Rope | 8.3mm | 8.3mm | 8.3mm | 8.6mm | 8.6mm/9.1 | ||

| Weight | Counterweight | 500kg | 750kg | 900kg | 1000kg | 1300kg | |

| Platform | Alu. | 280kg | 290kg | 340kg | 448kg | 528kg | |

| Steel | 310kg | 440kg | 480kg | 610kg | 630kg | ||

| Suspension Mechanism | 310kg | ||||||

| Electricity | Voltage | 220/380/400/415/440V as option | |||||

| Frequency | 50/60Hz | ||||||

| Phase | Three Phase | ||||||

| Safety Device | Safety Lock | LSB30 Anti-titling | |||||

| Overload Device | As option | ||||||

| Safety Harness | As option | ||||||

| Hanging Device | Suspension Mechanism | Projecting length 1.3m-1.7m | |||||

| Parapet Clamps | As option | ||||||

Q: What is the main material of aluminum alloy suspension scaffold?

A: The main material of aluminum alloy suspension scaffold is aluminum alloy, which is a lightweight high-strength material widely used in construction, aerospace, automobile manufacturing and other fields. Aluminum alloy has good corrosion resistance, lightweight characteristics and high strength, making it an ideal material for the manufacture of suspended scaffolding.

Q: What are the advantages of aluminum alloy suspension scaffolding?

Answer: The advantages of aluminum alloy suspension scaffolding mainly include:

Light weight: The low density of aluminum alloy material makes the overall weight of the scaffold light and easy to install and disassemble.

High strength: Aluminum alloy has high strength and can withstand large loads to ensure the safety of high-altitude work.

Corrosion resistance: Aluminum alloy has excellent corrosion resistance and can maintain a long service life in harsh environments.

Easy maintenance: The surface of aluminum alloy scaffolding is easy to clean and maintain, and can maintain a long-term good appearance and performance.

Q: What is the scope of application of aluminum alloy suspension scaffold?

A: Aluminum alloy suspension scaffold is suitable for a variety of high-altitude work scenarios, such as building construction, maintenance, decoration and cleaning. It is especially suitable for high-altitude working environments that require frequent movement and reassembly, such as curtain wall installation, exterior wall cleaning, etc.

Email us if you want our suspended platform and ODM/OEM service. We would be happy to answer your questions.

SKYLIFTEC Engineering Materials Co., Ltd. is a source factory and exporter, is also the leading supplier of contruction gondola lift in China.

Tel:+86 15630730058

Email: info@skyliftec@.com

Fax:

Address:Cangzhou City, Hebei Province, China.